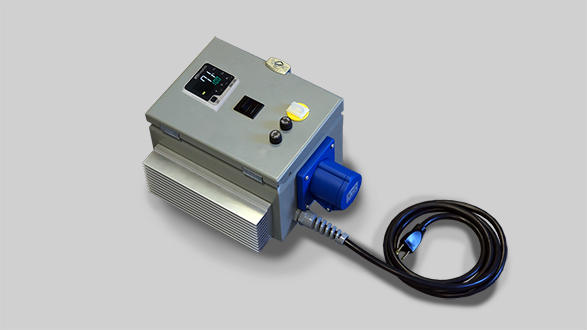

ABOUT SPECIAL-ZONE PID CONTROLLERS

Configurations are Bench-Top (BT) or Wall Mount (WM) arrangements. Let HTS/Amptek® help configure the ideal controller for you. Most heating solutions are easily solved with the standard available units. However, enhanced features such as communications, ELCI circuit interrupters, and many others can boost the application performance, monitoring and ease of use.

Frequently Asked Questions

Temperature control mechanisms are recommended for all types of heating tapes. We provide temperature controls with heating tape systems to make one cohesive network, and we utilize existing controls. There are a variety of control mechanisms available and the best choice depends on the temperature, voltage, accuracy and output used in your system. A mechanical bulb and capillary thermostat are recommended for temperatures below 325 degrees F. For voltage control a variable transformer or solid-state Triac controller may be used. For precise temperature control you can activate from a bench-top or wall-mount, we recommend the BT-15 or WM-15. We supply a complete list of thermostats and similar mechanisms, and we are happy to help you select the ideal device for your needs.

Can I Leave the Unused Portion Rolled Up?

No, your heating tape will not function properly if it is not touching the heat sink from end to end. Rolled up heating tape can be hazardous, so be sure your heating tape is completely and properly installed.

How Can I Tell Which Side is "Up"?

Heating tape exhibits a uniform temperature on both sides. Either side of the heating tape may be applied to the heat sink.

Can I Cut Heat Tape?

No. Heating tapes utilize constant electric flow throughout and are designed for a fixed resistance at a given length and voltage. The tape is pre-designed to suit your environment and attempting to modify it will destroy the tape.

How Does Heat Tape Work?

Heating tapes utilize a constant watt density at a fixed resistance over a fixed length and voltage to create heat. Heat output is based on a given input voltage. Heat transference to pipes, floors and other surfaces occurs through direct contact with the tape. An insulator surrounding the enclosed heating element stops the heat from escaping and maintains a desired temperature. Temperature controls integrated into the circuit allow you to control the temperature.

Why Is Heat Tape Temperature Different in Some Places?

The materials inside the heating tape determine the operating temperature. Different heating tapes utilize different materials to create and maintain a desired temperature.

Can I Hook Heat Tape Up to a Thermostat?

Heating tapes effectively integrate with a wide variety of temperature control devices such as: thermostats, variable transformers, Triacs, solid-state digital temperature controls, programmable logic controllers (PLC's) or computers.

Why do I need different sized heat tape?

The size of your heating tape is determined by a variety of factors, including a proper mechanical fit, heat output, voltage and temperature rating, among others. Expert installers at HTS/Amptek® Company will help you select the correct heating tape size for your application to ensure optimal energy efficiency, safety and durability.

What heat tape sizes can I choose from?

HTS/Amptek® Company supplies a range of heating tape sizes to give you the best fit. Our heating tape sizes are available on our price list and online store. When choosing your heating tape, be sure to consider the heat output, voltage and temperature rating involved in your application. If you are not sure which size is best for you, contact us and we are happy to assist you.

Features and Specifications

| Configuration: | Wall or Bench-Top Console |

| Enclosure: | Indoor, Metal, powder coated NEMA 1 |

| Supply Power Connectivity: | 120V, 240V Single Phase Power Cordset |

| Supply Voltage: | See above, Special Low Voltage DC availabe |

| Circuit Quantity: | 1, either Process or Process Limit |

| PID Logic: | On-Off, Autotune PID, Special Ramp and Soak |

| Power Switching: | SSR, Solid State Relay, Mechanical Relay Limit |

| Communications: | Special USB, rs485, rs232, or 4 - 20 loop |

| Sensors: | All Common Thermocouples or RTD |

| Power & Sensor Distribution: | Receptacles, Panel Mount or Pre-wired |

| Custom Designs: | Contact HTS/Amptek® |

TYPICAL AND SPECIAL FEATURES

Rugged Chassis Construction, Durable Components

Powder Coated steel used for Bench-Top and Wall Mount enclosures gives maximum durability. Components such as the SSRs are oversized to prevent duty-cycle failures.

Special Features for Communication, Timing and Ground Fault Protection

Component flexibility, such as enhanced PID modules can add a communication feature. Timers or Variable Voltage features may be added to solve prosses requirements. GFEC circuit interrupters can prevent harm to the operator and equipment by detecting a heater problem early.

Power and Sensor Extension Cables

Extension Cables are often the best solution to provide convenient hook-up when the Heater power and sensor leads are too short. Custom cables can be fabricated with Flex Conduit or SS Flex Armor for durability.

Contact: HTS/Amptek®

If you need something and don’t see it, call or email your questions. If we cannot do it, we will try to direct you to a resource that can. Click the quote button for a convenient form to help us with the size and scope of your application.