Blanket with Lacing Eye Closure for Clyndrical Vessel

Small Blanket, or Wide Tape with T/C Sensors

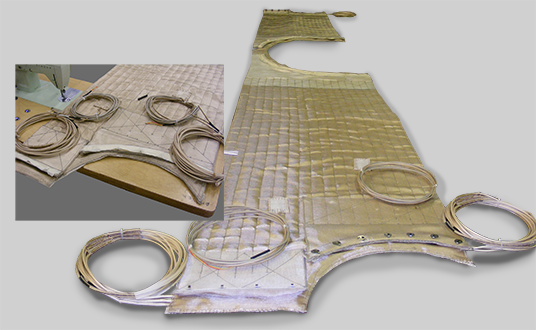

Large Format Twin Screw Conveyor Heating Blankets

Modular Design with Pre-Wired Power and Sennsor Leads

Flat Blanket, 3 Phase Power with Insulation and Closure Straps

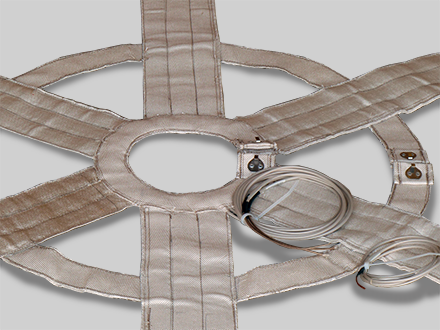

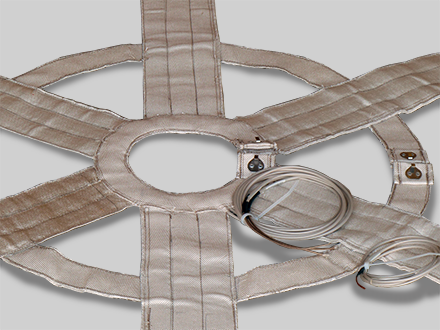

Star Shaped Flat Blanket for Dished Head Tank Bottom

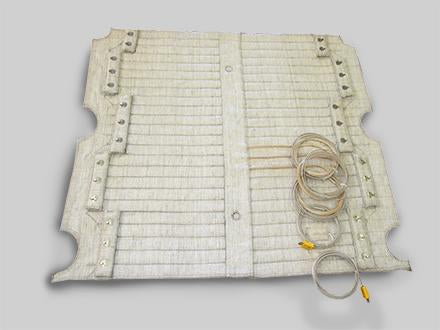

Small Blanket for Rectangular Tank

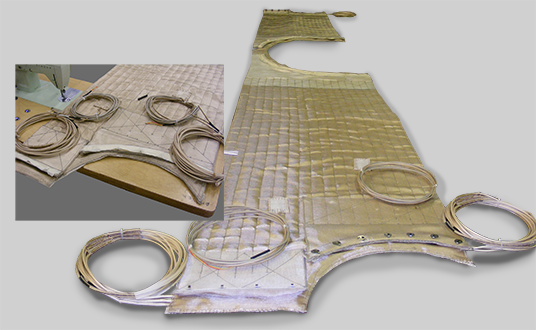

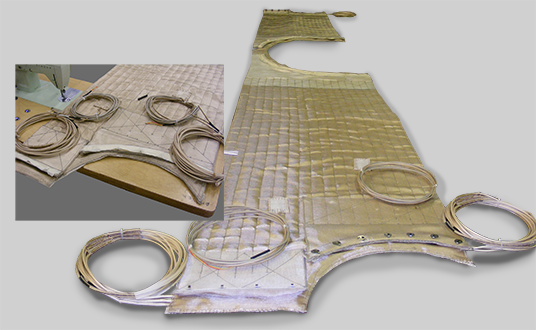

Preconfigured for Cutouts and Zone Wiring for Easy Installation

Custom Flat Insulated Blanket, Type K Thermocouple Sensor, Stainless Steel Tag

ABOUT FLAT HEATING BLANKETS

Custom Designed, insulated or uninsulated Flat Blankets, offer an elegant, efficient way to apply heat onto large surface areas. Flat, multi-piece designs offer a modular, easy to install solutions. Using low watt density efficient direct heat transfer, Blankets can offer an efficient alternative to large, expensive oven heating. Blankets may be built as small, tape-like formats or large, modular designs with many custom geometries. Flat Blankets start with an inner fabric liner and HTS/Amptek® knitted heat tape element then are closed incorporating outer fabrics with or without an insulation layer.

Frequently Asked Questions

Temperature control mechanisms are recommended for all types of heating tapes. We provide temperature controls with heating tape systems to make one cohesive network, and we utilize existing controls. There are a variety of control mechanisms available and the best choice depends on the temperature, voltage, accuracy and output used in your system. A mechanical bulb and capillary thermostat are recommended for temperatures below 325 degrees F. For voltage control a variable transformer or solid-state Triac controller may be used. For precise temperature control you can activate from a bench-top or wall-mount, we recommend the BT-15 or WM-15. We supply a complete list of thermostats and similar mechanisms, and we are happy to help you select the ideal device for your needs.

Can I Leave the Unused Portion Rolled Up?

No, your heating tape will not function properly if it is not touching the heat sink from end to end. Rolled up heating tape can be hazardous, so be sure your heating tape is completely and properly installed.

How Can I Tell Which Side is "Up"?

Heating tape exhibits a uniform temperature on both sides. Either side of the heating tape may be applied to the heat sink.

Can I Cut Heat Tape?

No. Heating tapes utilize constant electric flow throughout and are designed for a fixed resistance at a given length and voltage. The tape is pre-designed to suit your environment and attempting to modify it will destroy the tape.

How Does Heat Tape Work?

Heating tapes utilize a constant watt density at a fixed resistance over a fixed length and voltage to create heat. Heat output is based on a given input voltage. Heat transference to pipes, floors and other surfaces occurs through direct contact with the tape. An insulator surrounding the enclosed heating element stops the heat from escaping and maintains a desired temperature. Temperature controls integrated into the circuit allow you to control the temperature.

Why Is Heat Tape Temperature Different in Some Places?

The materials inside the heating tape determine the operating temperature. Different heating tapes utilize different materials to create and maintain a desired temperature.

Can I Hook Heat Tape Up to a Thermostat?

Heating tapes effectively integrate with a wide variety of temperature control devices such as: thermostats, variable transformers, Triacs, solid-state digital temperature controls, programmable logic controllers (PLC's) or computers.

Why do I need different sized heat tape?

The size of your heating tape is determined by a variety of factors, including a proper mechanical fit, heat output, voltage and temperature rating, among others. Expert installers at HTS/Amptek® Company will help you select the correct heating tape size for your application to ensure optimal energy efficiency, safety and durability.

What heat tape sizes can I choose from?

HTS/Amptek® Company supplies a range of heating tape sizes to give you the best fit. Our heating tape sizes are available on our price list and online store. When choosing your heating tape, be sure to consider the heat output, voltage and temperature rating involved in your application. If you are not sure which size is best for you, contact us and we are happy to assist you.

Features and Specifications

| Power density: | 1.0 to 12.0 watts/in² (0.16 to 1.5 watts/cm²) |

| Watts, Volts: | Custom KW, 120V/1 to 480/3ph |

| Size: | Custom Modular Sizes for Convenient Install |

| Weight: | Modular, 50lbs (23kg) Max Recommended |

| Heat Capability: | Operating Temperature to 1112°F (600°C) |

| Max Exposure: | 1400°F (760°C) |

| Power Leads: | A-Nickel or Cu-Ni, FLying, Sleever or Armored |

| Power Plugs: | NEMA, Straight, Twist Loc, Pin & Sleeve |

| Sensors: | Process & Limit Thermocouple or RTD |

| Area Class: | Non-Hazardous, Dry |

TYPICAL AND SPECIAL FEATURES

Blanket sizes:

Small Heating Blankets may be constructed like tapes to fit small pipes, vessels and fittings. Large Blankets are limited by weight, typically 50lbs (23kg), but may be constructed in multiples to fit large surfaces.

Construction:

An inner liner has the mechanically attached heating element and sensors. Then insulation layers may be placed over top with gusset and outer fabrics to enclose the assembly. All Blankets are fabricated to fit the area to cover and double stitched for durability. The materials of construction depend upon the temperature and environment of use. Below 550° F choices can include materials such as Teflon and Silicone, which provide durability and some moisture protection. High temperature Blankets, are constructed of safe fiberglass based fabrics with Fiberglass or Ceramic insulations. Moisture resisting materials or grounding planes may be placed over as a final outer cover.

The Heating Element:

HTS/Amptek® knitted Heating Tape is stitch bonded to the liner of each Blanket to apply the heat where needed. Monotape™ and Duo-Tape® elements are multi-strand insulated resistance wire, knitted into serpentine strips allowing ultimate flexibility that eliminates thermal stress.

Temperature Capability:

900°F (482°C), or AMOX™ to 1400°F (760°C). However, temperatures exceeding 1112°F exposure, are not recommended if the Blanket would need to be manipulated once in place. (removed and reinstalled)

Heated Zones:

Typical Blankets have a single zone, however, multiple zones may be arranged having individual power leads and sensors. This arrangement can offer zonal duty-cycle for ultimate control.

Temperature sensors:

Built in thermal sensors such as RTDs or Thermocouples can be installed for process temperature measurement, or directly on the heating element for sensing limit temperature.

Cutouts and Penetrations:

Cut outs and slits for supports, ports and other hardware are typical of most applications. HTS/Amptek® designs preformed Blanket configurations with holes, slits and seams to provide great fit and easy install and removal. Additional flaps and straps cover the exposed seams.

Closures:

Most common Closures are lacing hook or eyelet flap closure methods.

Contact: HTS/Amptek®

Call or email your questions, or click the quote button for a convenient form to help us with the size and scope of your application.