Vessel Heaters

Vessel heaters, both large and small, are devices designed to heat liquids or gases contained within vessels or tanks. They are commonly used in various industrial processes, such as oil refining, chemical production, food processing, and water treatment, among others.

Large vessel heaters are typically used in industrial settings where large volumes of liquids or gases need to be heated, or where vacuum bake-out is required. They are often custom-designed to suit specific applications and can handle high flow rates and large capacities. Large vessel heaters may utilize different heating methods, such as electric immersion or surface heating elements, steam, or hot water circulation systems, depending on the requirements of the process.

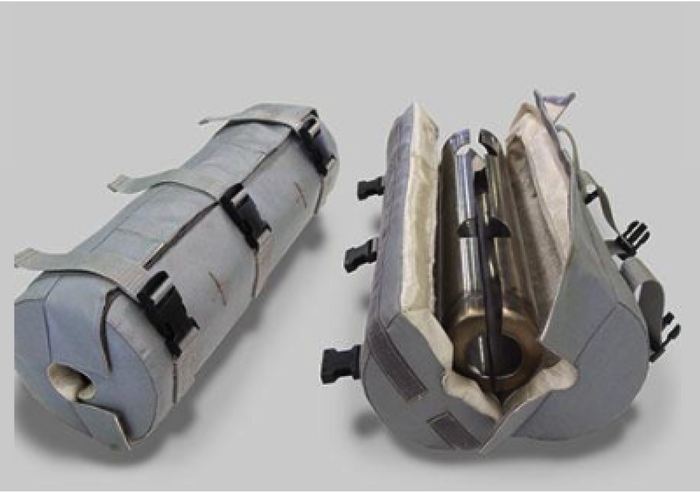

Small vessel heaters, on the other hand, are generally used in smaller-scale applications, such as laboratories, research facilities, or small production setups. For example, flexible electric heating elements such as Tapes, Blankets or Jackets are often used to simulate the other heaters such as steam or fired heat exchangers.

The specific design and features of vessel heaters can vary depending on the application and the requirements of the process. Some common features include temperature control systems, safety mechanisms, insulation to minimize heat loss, and materials suitable for the specific medium being heated.

It's important to note that the above information provides a general overview, and the actual design and specifications of vessel heaters can vary significantly depending on the specific industry, process, and requirements.